The 2-stroke cycle

|

Internal combustion engines (with rare exceptions) operate on either a 2-stroke or 4-stroke cycle.

In both types, each full rotation of the crankshaft produces two strokes of the piston, one moving inwards towards the head of the cylinder, followed by a second which withdraws the piston back to its initial position. A 2-stroke engine fires once every rotation of the crankshaft (every second stroke of the piston) when the piston has compressed the fuel/air mixture. The most common applications of the 2-stroke principle are in motor-cycles, lawnmowers and other small tools and light machines. In these applications, the fuel is usually petroleum spirit (gasoline) and the engines valveless, the cylinder and piston being designed in such a way that the fuel/air mixture is drawn-in and the burnt gases are exhausted at the correct point in the cycle by the motion of the piston alone. These engines tend to run at high piston speeds to achieve maximum efficiency. |

Less common are 2-stroke diesel engine designs. They have been produced over a long period of time and in many different forms, some outstandingly successful (e.g. Napier Deltic), others competent and some best forgotten!

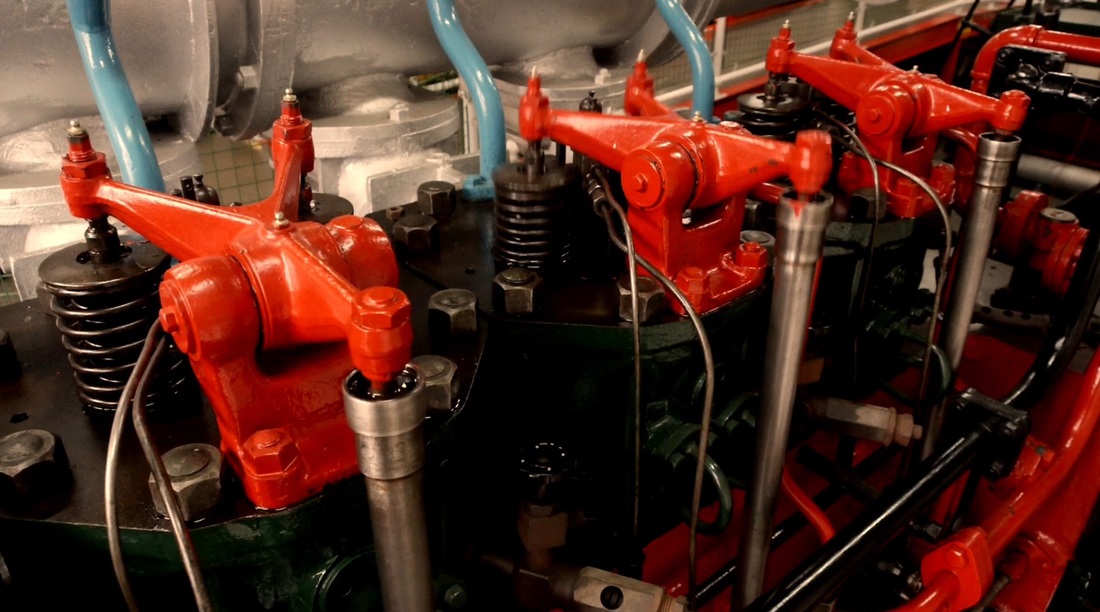

Our collection includes two 2-stroke diesels, one normally-aspirated (Vickers-Petter), the other pressure-charged (W H Allen T47). The T47 is also unusual in that (similar to a 4-stroke engine) it incorporates exhaust valves to control the emission of the burnt gases. Back to Engineering |